PSMS Lessons Learned - January 2026 - Proper Materials

January PSMS 2026 Lesson Learned

Failure to use proper materials may introduce a safety hazard

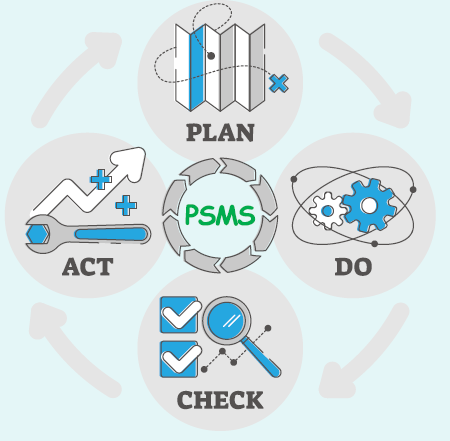

API RP 1173 is a framework for implementing a safety management system, not a technical specification. So, it does not require specific materials, but it does require processes that ensure equipment, components, and materials utilized in your system conform to your organization’s standards. The requirement to best ensure approved materials are utilized is captured primarily under Element 7 (Risk Management).

Element 7 requires operators to have structured processes to identify hazards, assess risks, and put controls in place to mitigate them. This includes ensuring equipment and components used in operations do not introduce hazards such as using incorrect or non‑compliant materials.

Why this element applies:

Using materials that meet your organization’s specifications is viewed as a “risk control.” Failure to use proper materials could introduce a safety hazard, which Element 7 requires operators to address.

Description of Event:

A Customer's house line was over pressurized when the service regulator vent termination fitting, became dislodged, and water entered the regulator's diaphragm assembly through vent piping. The regulator was a Gas Service Regulator set inside the customer's basement with the vent piped to the outside. The vent termination fitting was a “mushroom style” termination fitting (a.k.a. “vent cap” / “vent protector”).

Key Causal Factors/Root Causes:

1- The mushroom style regulator vent cap dislodged.

2- Mushroom vent caps did not meet the organizations requirements for vent caps.

Key Corrective Actions:

The organization implemented a QA/QC inspection process for service regulators and regulator vent piping within the regional service territory. The action will help identify and weed out any remaining mushroom style vents.

In addition, Customer Service and Leak Survey team members have been made aware that these regulator vent styles may still be in the service territory throughout the region and must be identified, reported and/or addressed when encountered.

Key Lessons Learned:

- Regulator / relief vent terminus shall be a minimum of 12 inches above outside grade; however, 18 inches is recommended.

- The vent terminus shall have a screened vent cap to prevent entrance of insects.

- The vent cap shall be faced down to prevent water intrusion / accumulation.

- The vent cap shall be labeled as gas vent.

- Only approved materials shall be used in M&R set construction and maintenance, if alternate material is considered the local area supervisor shall be contacted prior to utilizing the alternate material or construction practice and a Management of Change Process will be applied.

Bottom Line

The use of proper materials that meet organizational requirements is not spelled out explicitly in API RP 1173, but it is required indirectly through the management system elements—primarily Element 7: Risk Management

Normalization of deviance remains one of the greatest PSMS threats that can impact personal safety, process safety and pipeline safety.

Don’t fall into the “normalization trap” by following all procedures and specifications ALL the time, and when a situation prohibits this practice, notify your supervisor immediately and practice your organizations MOC Procedures.

Additional January Safety Reminder

Meter & Regulator Set Safety in Snow & Ice Conditions

Please be reminded that meter protection is critical when adverse winter weather conditions occur. Please practice the following during these conditions:

- Be careful using a shovel, snow blower or snowplow when clearing snow and ice near your natural gas meter.

- Keep your natural gas meter and equipment free of snow and ice by carefully removing accumulation by hand, brush or broom.

- Do not use sharp objects, salt, ice melting chemicals or hot water to remove snow and ice.

- Look up! Cautiously remove ice hanging from roof edges above your natural gas meter.

- Clear your natural gas appliance vents and air intakes of potential obstructions.