PSMS Lessons Learned - Defense-in-Depth - May 2025

May 2025 PSMS Lessons Learned

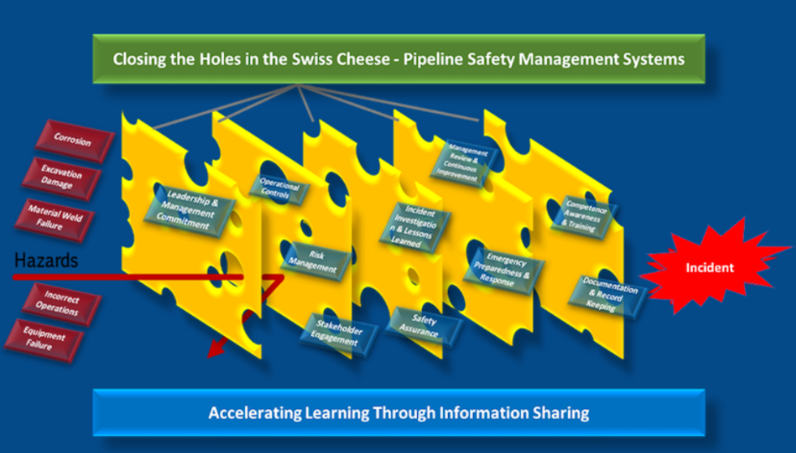

"Defense-in-Depth"

The framework of API RP 1173 was developed to enhance pipeline safety through a holistic “risk based” approach that integrates “layers of protection” through the ten elements. Failures can occur when multiple elements are compromised as illustrated in the “Swiss Cheese Model.” Two key aspects of a successful Pipeline Safety Management System that require constant focus, and are sometimes overlooked, are maintaining up-to-date documents and records as well as engaging all stakeholders, including employees and contractors. These elements are a critical part of managing risks when conducting our day-to-day operational activities.

Description of Event:

While a Contractor was excavating to install a new gas transmission main in the roadway, they came into contact with and damaged an existing 6” plastic 60 psig gas main. The damage resulted in a release of gas and unplanned supply interruption to six (6) customers. The contractor had previously performed test holes to locate the distribution gas main and identified the main behind the curb. Mapping had shown the main in the road, but the roadway had been changed in the decades since the main install. Attempts to locate with the tracer wire also placed the gas main behind the curb, but signal was weak due to the depth of the main under thick asphalt cover. Several years earlier, in project design, test holes were performed by another third-party contractor and the main was not identified in the roadway. The third-party locator was actively working on the project with the excavator and had entered an 811 ticket locate response as “unknown address,” which was not the typical or expected response of “marked” or “clear/no conflict.”

Key Causal Factors and Root Cause(s):

- Primary Causal Factor: Multiple test holes determined the prints were incorrect and the gas main was approximately 9 feet behind the curb north of the roadway.

- Root Cause: Management System – Standard Policies Admin Controls Need improvement (NI) – Drawings/Prints NI

Key Corrective Actions:

- Construction to perform a safety stand down to review incident with the contractor.

- Construction to share the IA details with internal team and Contractors.

- Route Contractor problem locate ticket details back to Construction for additional review prior to work commencing.

- Damage prevention will share information that “Incorrect Address” is not a positive response for 811 even though it shows a ticket as active.

- Contractor will train employees on positive locate responses for 811 tickets.

- Contractor refresh and retrain crew on Task 71 – “Operator Excavation in the Vicinity of a Pipeline.”

- Contractor to update their internal job brief system with proper positive response reviews.

Key Lessons Learned:

Maintaining open dialogue with locators on complex projects is critical to ensuring that markouts are completed accurately and thoroughly.

- The Contractor followed best practices and called a safety stop at several points when they could not locate the main or it did not enter their trench where expected.

- A positive marked response is needed on 811 tickets. Exercise Stop Work Authority - Mechanical excavating should not occur unless a known positive marked or clear response is received. Trust but Verify - Contractors should call in to 811, the locator, or operator if there is uncertainty around the response received.