PSMS Lessons Learned - September 2025 - Materials

Verifying Materials is Critical to Pipeline Safety Activities Avoiding Pitfalls of Normalization of Deviance

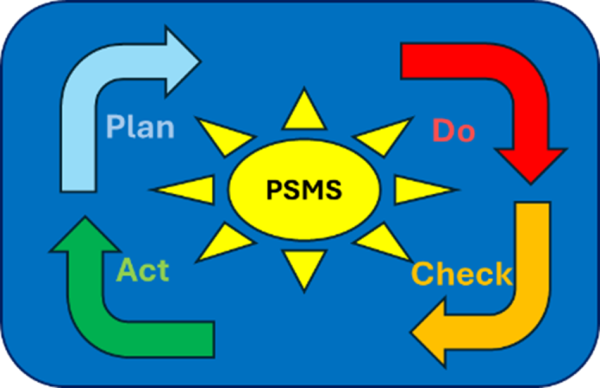

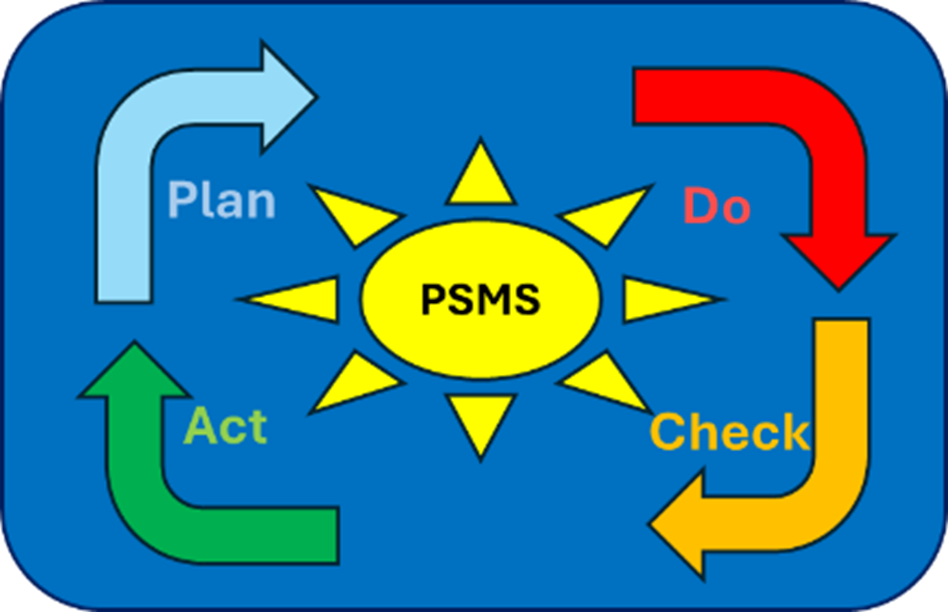

Verification of job materials and compatibility of components is considered a critical component of managing risk as part of your day-to-day work regarding pipeline safety management systems. Ensuring that the materials used in construction, maintenance, or repairs meet the job specifications requirements is essential. The NGA PSMS Mains and Services Construction Tactical Guide focuses on a Plan-Do-Check-Act approach for continuous improvement and suggests in the Planning Phase under “Procedures and Planning” to perform a Pre-Mobilization Review before beginning work in the field. This activity involves the Engineering Designer, Inspector, Field Supervisor, and Installer reviewing the Work Package before going on-site. The “Pre-Mobilization Review Section of the Guide specifically calls out a STOP if any changes have occurred that might affect the overall safety of the work. This includes “hand-offs” as well.

Description of Event:

The original work order was designed by engineering in 2022 but put on hold. In 2023, the division began using HDPE pipe with SDR 11, but a design reevaluation was not performed, despite SDR 11 being in stock. The storeroom did not verify that all required materials were available before releasing them to the contractor. The contractor later picked up 1.25” HDPE SDR 11 coil pipe after running out of SDR 10. The storeroom does not check if materials issued match SDR because it is the responsibility of engineering, and storeroom does not make recommendations.

When installation began in the fall of 2024, the contractor did not verify SDR compatibility of components, and the inspector did not catch the error. The installation passed a leak test.

After incorrect tees were fused and the mismatched service pipe was inserted, the issue was discovered by the Gas Supervisor. Gas Operations chose not notify engineering. Instead, the contractor and Gas Operations team planned remediation without a written procedure from engineering. During the repair, a squeeze-off was performed to isolate the work area. A bypass was not used because the system was incorrectly thought to have been looped or dual-feed. The contractor monitored pressure gauges for 20 minutes, saw no change, but later found the gauges at zero. In a low-pressure system with 108 meters, functional pressure is unlikely to remain after 20 minutes.

Engineering, responsible for design and procedures, was excluded from operational decisions. The response team was assembled and deployed to shut off, repair, and relight. No compliance or safety concerns were reported during the response efforts.

Key Causal Factors/Root Causes:

1. Contractor was not aware they installed a service tee with wrong service pipe material (SDR 11 instead of SDR 10).

2. On-site Construction Inspector did not sufficiently inspect materials installed and identify a wrong SDR was used.

3. Local Distribution Supervisor gave directions to cut out and replace service tee with correct SDR. Original components were installed on 9/25; remediation was on 10/09.

4. Contractor began work to replace components on main and squeeze-off the section to be remediated, since it was believed to be a loop feed. Soon after, gas outage calls were received because the system was a single-feed supply. Contractor was responsible for monitoring gauges during squeeze off but obviously failed to do so. Outage occurred, losing 108 customers.

5. The operations team was responding to an abnormal situation while in a knowledge-based performance mode. Gas operations failed to obtain a written engineering procedure for the remediation and resulted in a customer outage. The company’s competent engineer plan was not followed.

Key Corrective Actions:

1-2. Safety standdown was performed - Contractor Qualifications were pulled and made to re-qualify. Notice was made to stores and new processes are in place to prevent this from happening again. Materials issuance procedure was discussed.

3. Immediate Corrective Action: Outage occurred losing 108 customers. A repair was made and restored service to customers. Multiple meetings were conducted afterwards between Gas Company and Construction Contractor resulting in OQ's being pulled for the crew that was performing work.

4. Held Meeting and reenforced the importance of following the competent engineer plan. Non-conformance reports were submitted, and corrective action plans were devised.

5. Aged work orders updated and reviewed before release.

Key Lessons Learned:

1. Material Verification is Critical

a. All materials must be verified against engineering specifications before release.

b. Storeroom must not allow substitute materials to be issued without engineering approval.

2. Engineering Must Be Involved in All Phases

a. Engineering should be consulted about any material changes or remediation plans as excluding them increases risk and non-compliance.

b. Written procedures from engineering are mandatory for critical operations like squeeze-offs.

3. Strict Adherence to Construction Standards

a. Deviations from standards can lead to safety and service issues. Contractors must be trained and held accountable for following specifications.

4. Inspection Protocols Need Reinforcement

a. Oversight failures can allow critical errors to go unnoticed.

b. Ongoing evaluation of contractor performance is essential.

5. Pressure Monitoring Must Be Continuous

a. Gauges must be actively monitored during live gas operations.

NOTE: A PSMS Tactical Guide Guiding Principle for Field Workers: “Adhere to engineering design standards, work packages, company procedures, specifications, processes & use of approved material & equipment – identify & communicate procedural/material deficiencies. Do not perform “Work Arounds” and if necessary, stop the job.” The bigger question we need to ask ourselves is what drives personnel human behavior and the belief not following a procedure and that “workarounds” are an acceptable practice ?? Address this behavior is key to sustainable culture change. We have procedures, we have training, we have qualification programs……. Why do we continue to see normalization of deviance…..?