PSMS Lessons Learned - October 2025 - Breaking down “Silos of Safety"

October 2025 PSMS Lessons Learned

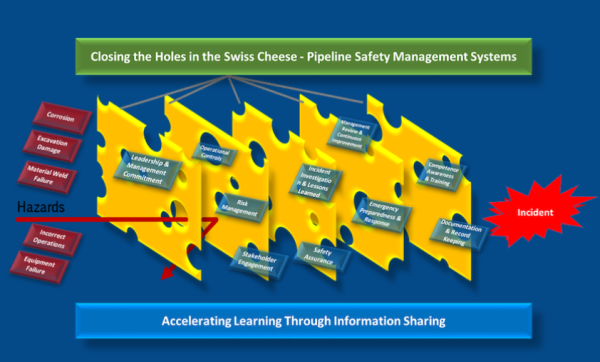

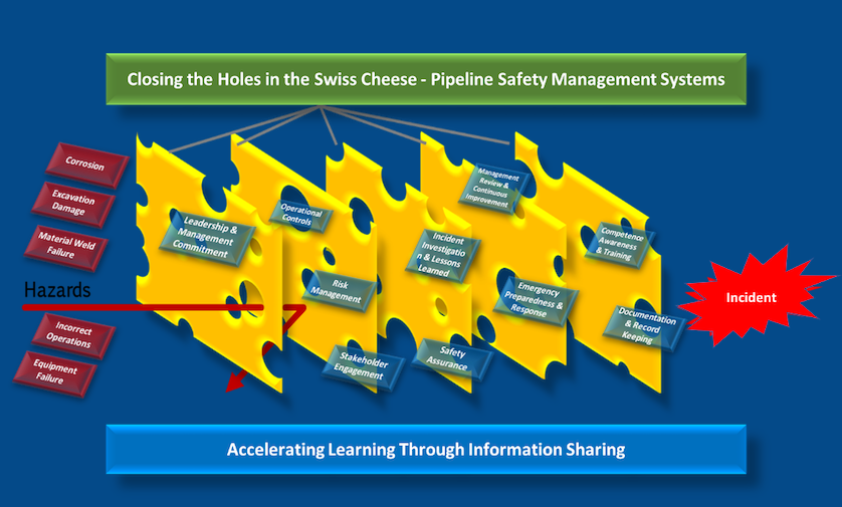

“Breaking down “Silos of Safety" - Connecting Essential Elements of Pipeline Safety, Process Safety and Personal Safety.

Communication & Situational Awareness, Calibration of Instruments, Good Record Keeping Together Play a Critical Role in Pipeline Safety Management

Effective communication and situational awareness, as outlined in API RP 1173 (Elements 2 & 9), are critical for pipeline safety, ensuring timely sharing of calibration data and operational status to prevent risks like equipment failure. These processes rely on good record keeping maintaining traceable, accessible calibration logs and communication records, enabling quick reference and trend analysis (Element 10). Calibration of critical instruments (Element 4) ensures accuracy, with updates managed and communicated to maintain awareness. Together, these elements create a cohesive safety system, reducing incidents through informed, proactive operations.

Description of Event:

An LNG facility began the liquefier start-up at 12:06 following a shutdown related to an electrical brown out. At 15:15 Dispatch began receiving numerous leak calls across the 15 PSIG system within the service area. Liquefaction start-up continued with liquid being sent to the tank at 15:30. Further investigation yielded that high odorant levels were received locally on equipment designed to monitor mercaptan on the outlet of the liquefier’s tail gas line that feeds the 15 PSIG system and further downstream at an additional Gate Station monitoring point.

Key Causal Factors/Root Causes:

- Primary Causal Factor: Instrumentation (level indication of heavy hydrocarbon knockout drums within Cold Box) readings were questionable leading to carry-over of mercaptan rich gas.

- Root Cause: Equipment Difficulty – Preventative/Predictive Maintenance – Preventative Maintenance (PM) Needs Improvement (NI) – PM for Equipment NI

- Causal Factor: System Operator monitored system for subsequent odorant readings at downstream Gate Station - no notifications of elevated mercaptan/odorant indications made outside of Gas Control.

- Root Cause: Communication – No Communication or Not Timely to the Plant Operator – Late Communication

- Causal Factor: The LNG tail gas odorant readings may be unreliable – No record of instrument calibration or maintenance / PM being completed.

- Root Cause: Management System – Standards, Policies, or Admin Controls (SPAC) NI – SPAC Not Used – Enforcement NI

Key Corrective Actions:

- Develop detailed PM procedure for level indicator instrumentation for knockout drums.

- Establish bi-weekly manual review of open maintenance and outstanding work orders.

- Develop detailed PM procedure for odorant/mercaptan tail gas monitor including the Control Room reading indication and communication to GSO (Gas System Operations) SCADA.

- Automated E-logger entry for high and high-high odorant alarms on the 15 PSIG monitoring instrument located at the downstream Gate Station.

- Add Dispatch to E-logger LNG status updates to enhance communication between Plant/System Operations organizations.

Key Lessons Learned:

- Communication between cross-functional teams must be timely and concise, even when all information is not known, to increase situational awareness.

- Process instrumentation and controls need to be calibrated and tested to ensure good working order.

- It is critical for contractors performing maintenance work to submit timely and complete records of maintenance activities.

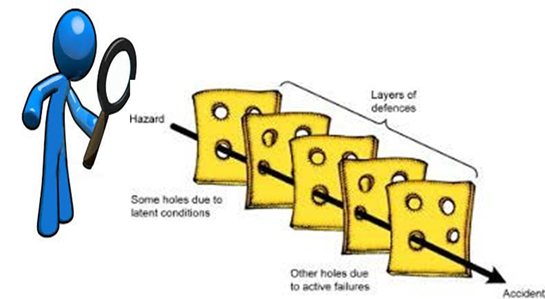

This situation highlights the connectivity of essential elements of safety management systems in preventing the “holes in the swiss cheese” from lining up resulting in a safety related failure. Breaking down institutional “safety silos” associated with pipeline safety, process safety and personal safety help us all connect-the-dots of core elements of safety management system principles including Operational Controls, Effective Communication and Documentation. Keep an eye out for a planned NGA Seminar that will help you better understand the practical side of connecting elements of process safety, personal safety and pipeline safety !